In the electronics industry, packaging plays a critical role in protecting sensitive components from damage and ensuring the safe delivery of products. Given the delicate nature of electronic devices, it’s essential to use specialized packaging materials that offer protection from static electricity, physical shocks, and environmental factors.

Packaging Supplies by Industry: What You Need to Know

Choosing the right materials to package and ship your product is crucial no matter what industry you are in. Packaging not only protects your product but also plays a significant role in branding, compliance, and customer satisfaction.

Different industries have unique packaging requirements that must be met to ensure product safety, regulatory compliance, and market appeal. Below, PackageIt explores the specific needs in a few larger industries and looks at why it’s important to partner with a knowledgeable supplier for this process.

Electronics Industry

Electrostatic Discharge (ESD) Protective Packaging

Electronics are highly sensitive to static electricity, which can damage components. ESD protective packaging, like shield bags and bubble wraps, is essential to prevent static discharge during storage and transportation.

Cushioning Materials for Fragile Components

Electronics often contain fragile components that need to be protected from shocks and vibrations. Cushioning materials such as bubble wrap, biodegradable inserts, and padded boxes are necessary to ensure safe delivery.

Moisture Barrier Bags for Protecting Sensitive Devices

Moisture can cause significant damage to electronic components, which is why moisture barrier bags are essential to protect sensitive devices from humidity and moisture during shipping and storage.

Labeling Requirements for Electronic Products

As mandated by the Fair Packaging and Labeling Act, electronics need proper labeling to provide critical information such as model numbers, serial numbers, safety warnings, and usage instructions. Compliance with labeling standards ensures product safety and traceability.

Cosmetics and Personal Care Industry

As e-commerce continues to flourish, we can expect even more growth in online cosmetics and personal care niches. Thus, there’s a need to address the specific packaging requirements for these products.

Packaging Supplies That Protect Sensitive Ingredients

Cosmetics and personal care products often contain sensitive ingredients that can degrade if exposed to air, light, or contaminants. Packaging must protect these ingredients to maintain product efficacy and safety.

Airless Pumps and Dispensers for Preserving Product Integrity

Airless pumps and dispensers are popular in the cosmetics industry as they prevent air from entering the packaging, thus preserving the integrity and shelf life of the product.

Attractive Packaging Designs for Shelf Appeal

Packaging design plays a crucial role in attracting consumers. In a competitive market, visually appealing packaging that follows your branding message can make a significant difference in a product’s success.

Sustainable and Eco-Friendly Packaging Options

With increasing consumer awareness about environmental issues, sustainable and eco-friendly packaging options are becoming more important. Using recyclable or biodegradable materials can enhance your brand’s reputation and appeal to environmentally conscious consumers.

Food and Beverage Industry

For the food and beverage industry, packaging materials must meet stringent safety standards to ensure that the packaging materials do not contaminate the food. Food-grade materials are essential to maintain the quality and safety of the products.

Food Temperature Matters

Different types of food require different packaging solutions. For example, dry foods need airtight containers to prevent moisture, while liquids need leak-proof bottles or cartons. Frozen foods require materials that can withstand low temperatures while keeping the air insulated.

Tamper-Evident and Resealable Packaging Options

Tamper-evident packaging ensures that the product has not been altered or contaminated after production. Resealable packaging options are also crucial for maintaining the freshness of the product after opening.

Labeling Requirements for Food Products

Food packaging must also comply with labeling regulations set by the FDA, CDC, and other organizations. These requirements include nutritional information, ingredients, allergens, and expiration dates. Clear and accurate labeling is essential for consumer safety and compliance with regulatory standards.

Pharmaceutical and Medical Device Industry

The healthcare industry is another niche that has highly specific packaging needs. Here are a few of the biggest considerations.

Sterile Packaging Requirements

In the pharmaceutical and medical device industry, maintaining sterility is paramount. Packaging must protect products from contamination and maintain sterility until the point of use.

Tamper-Evident and Child-Resistant Packaging

To prevent unauthorized access and ensure safety, pharmaceutical packaging often includes tamper-evident and child-resistant features. These are critical for protecting consumers, especially children, from accidental ingestion.

Compliance With FDA Regulations

Pharmaceutical packaging must also comply with FDA regulations, which covers everything from material safety to labeling requirements. Non-compliance can result in severe penalties and product recalls.

Wrapping Up: The Packaging Needs of Various Industries

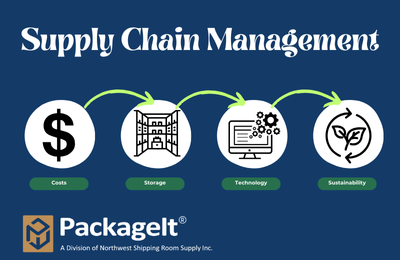

Choosing the right packaging supplies tailored to specific industry requirements is essential for product safety, compliance, and customer satisfaction. We recommend working with a knowledgeable packaging supplier like PackageIt for the best results. We provide invaluable expertise and a comprehensive range of products to meet these needs.

With our help, you can access quality packaging and custom options that not only protect your products but also enhance your brand image and ensure regulatory compliance. Browse our extensive catalog and speak with a specialist today!