Streamlining Order Processing

The real challenge is processing and handling the influx of orders efficiently. The solution? Digital tools and a centralized

order management system (OMS) that help you track, confirm, and prioritize every order.

An OMS oversees an order’s lifecycle, from its entry to fulfillment and after-sales support. Let go of those spreadsheets and manual updates and get real-time insights instead.

Of course, automation alone is not enough. You must also maintain real-time visibility of inventory and production schedules across all sales channels. After all, how can you accept more orders than you can fulfill?

Every product and material counts; visibility is what keeps operations running smoothly and customers satisfied.

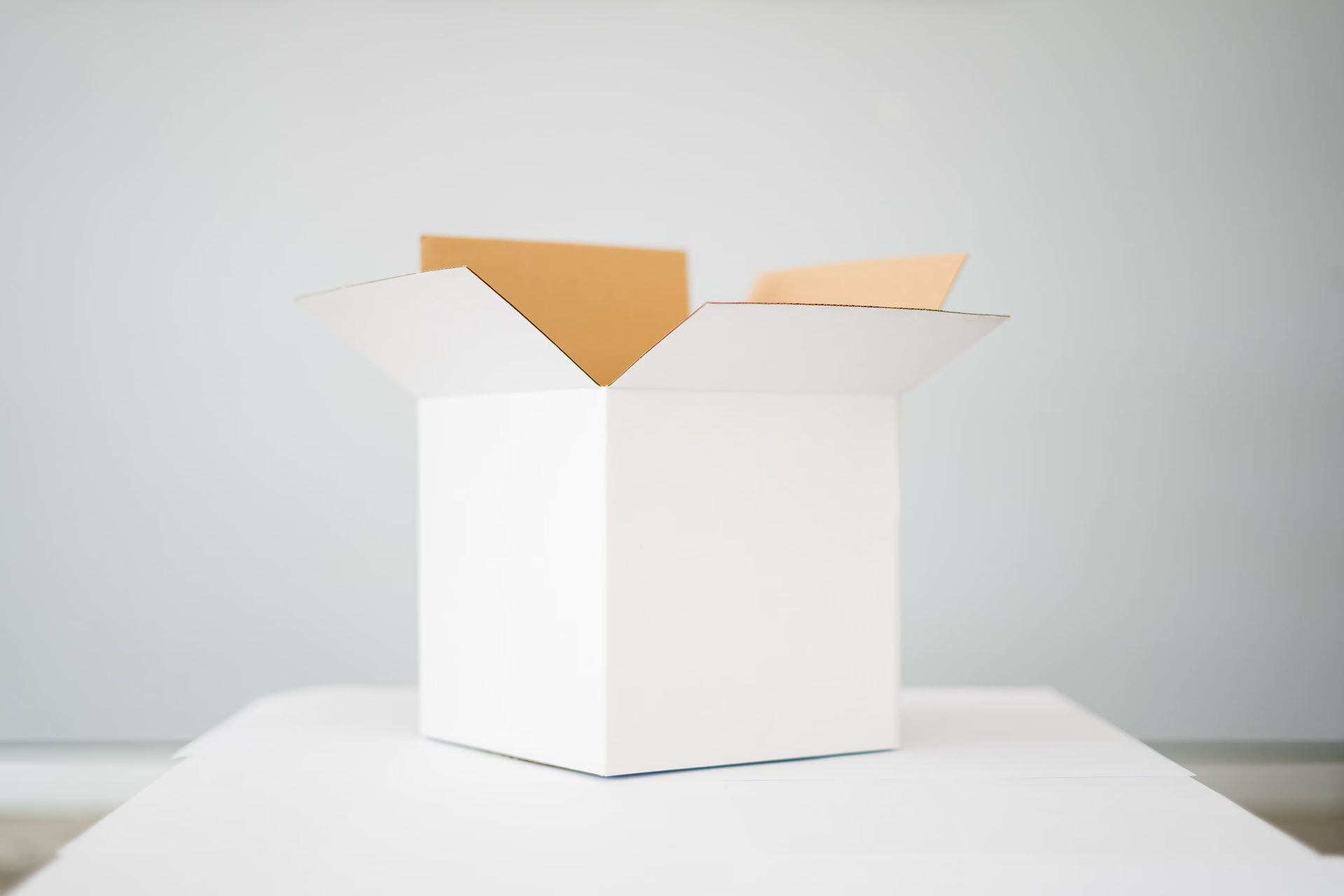

Optimizing Fulfillment and Quality Control

Are the orders confirmed and queued? Excellent.

Next, execution.

Did you know that

45% of consumers are more likely to buy from retailers offering premium packaging? Implement standardized procedures for picking, packing, and quality control. Even simply implementing visual checklists or barcode scanning goes a long way.

Moreover, many customers cite damaged products as one of the main reasons for returns and negative reviews. No matter how many thousands of orders you must box, never cut back on safety because shipping can get literally bumpy!

Minimal thought in packaging design can result in broken goods, frustrated buyers, and lost revenue. Plus, every return shipment adds to your costs and environmental footprint.

What should you do then? Focus on right-sizing packaging and kitting, and keep in mind that 75% of consumers are willing to pay more for sustainable packaging. They are now better at identifying which brands really walk the talk.

Those

recyclable materials, compostable fillers, and FSC-certified paper? They are your selling points. Use them not only because you want profit and savings, but also because the planet needs you to.

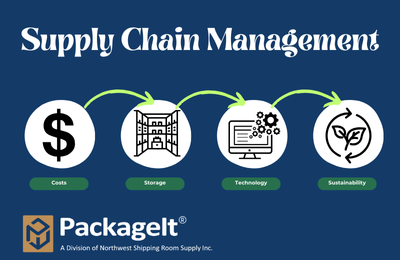

Leveraging Technology for Scalability

When it comes to order fulfillment best practices, one of the smartest investments is technology. Warehouse management solutions scale and synchronize everything! Here are some

major tech tools to consider:

- Tracking. Technologies like RFID and GPS track products, materials, and shipments. Know where everything is, all the time.

- Transportation. Automated guided vehicles (AGVs), self-driving forklifts, and drones transport goods through warehouses more efficiently and safely.

- Robotics. Robots are now widely used for picking, sorting, and packing tasks, often working alongside human operators for speed and consistency.

- WMS (Warehouse Management Software).

Oversee complete warehouse functions, from inventory and space allocation to workflow optimization.

- Artificial Intelligence (AI).

AI analyzes large data sets to improve nearly every aspect of your packaging and fulfillment operations, including demand planning, production scheduling, and route and cost optimization.

In other words, technology handles more orders and does so smarter. Do not overlook the power of real-time customer communication, either. Multichannel fulfillment tools that provide customers with live updates and status notifications help build trust and reduce service inquiries. The more customers know, the less they will ask of you.

Proactive Problem Solving and Continuous Improvement

It’s frustrating to still encounter hiccups after setting up

the best systems. Materials may run short; buyers make last-minute changes; delivery routes get disrupted, and all sorts of nightmares happen. Challenges are a part of reality!

What separates successful businesses from others is how quickly and calmly they respond to challenges. How do you do this? Establish clear protocols for urgent requests, returns, and adjustments. Your team must know exactly what to do, so nobody panics or points fingers during or after a rush.

Make regular performance reviews a part of your routine as well. How are your on-time delivery, order accuracy, return rates, and other KPIs? A drop may mean it’s time to adjust staffing levels, retrain people, or revisit your carrier methods.

Simply put, don’t wait until there’s a problem. Prepare for it, then take small, consistent steps to improve daily.

Let Us Support Your Order Fulfillment Best Practices

Managing high-volume packaging orders is usually chaotic. There’s

a lot at stake, and businesses cannot just “go with the flow.” Fortunately, with foresight, the right tools, and dependable partners, you can win.

Again, start with a plan based on the trends and upcoming promotions, and communicate clearly with your packaging partners. Then, streamline your processing with automation and real-time visibility, and refine fulfillment through standardization, quality checks, and the use of sustainable materials.

Leverage technology for scalability and smart data-driven decisions, and, most importantly, continuously improve through proactive problem-solving and KPI tracking. Do and get better

every day. Bring all these strategies together, and you will be well-prepared for whatever the market throws your way.

At PackageIt, we are eager to provide guidance and streamlined solutions that keep your business running smoothly, order after order.

Connect with our team today, and let us simplify your large-scale custom packaging management.