Businesses understand the value of packaging well, as it helps define a brand

and protect products, both of which are crucial for customer satisfaction and loyalty. In fact,

45% of consumers say they are more likely to buy from a retailer that offers premium packaging.

Unfortunately, packaging supply chains are facing a challenge: waste. Overstocking, obsolescence, and damage. All three hurt the planet

and your business.

At PackageIt, our solution is vendor-managed inventory (VMI). Let us reveal what this is and how exactly your brand and operations can benefit from it.

What Is Vendor-Managed Inventory (VMI)?

The Packaging Waste Problem

Why do vendor-managed inventory packaging solutions matter? Because we can no longer deny that packaging waste has become one of the most persistent and expensive inefficiencies for businesses.

- Overstock: Since packaging is such a visible aspect of a brand, companies tend to stock

too much of it. As a result, shelves get filled with excess packaging that might never be used.

- Obsolescence. As designs evolve or product lines change, outdated packaging materials can accumulate. By having a “safety net,” you could end up with a warehouse full of wasted resources.

- Damage. When packaging sits too long or is improperly stored, it deteriorates. Damaged boxes and warped materials result in damaged goods, worsening the waste problem.

Financially, the impact of packaging waste is significant. Packaging accounts for approximately 10% of a product’s total cost, ranging from a few cents to several dollars per unit. Imagine simply throwing this money away.

Some consequences also affect the environment.

Roughly 40% of the world’s plastic waste comes from packaging alone. Every unit you order has the potential to become a part of that statistic.

How VMI Reduces Packaging Waste

So, how

does

VMI contribute to reducing packaging waste? Here are five ways.

Lean Inventory Management

Packaging inventory management keeps stock lean by maintaining only what is

currently required and what will be required in the near future. You receive shipments aligned with your actual consumption, preventing surplus materials.

Improved Forecasting and Demand Planning

VMI leverages sales data, production schedules, and insights into seasonality. This accurate forecasting avoids overproduction and shortens lead times. With a plan based on

real

numbers, you cut down on unnecessary orders and wasted resources.

Avoidance of Obsolete or Expired Stocks

Through a “first in, first out” approach, no unit expires or becomes outdated. Packaging inventory management done by your vendor comes with tight control, ensuring you consume older stock before newer supplies arrive.

Reduction of Product Damage

With suppliers overseeing and handling your packaging materials, you don’t have to worry about damaging them. Rest assured, they are appropriately stored and regularly rotated, so you can expect fewer boxes and papers to discard and more consistent product protection.

Reduced Need for Bulk Storage

Do you have space for that bulk inventory? Even if you do, you could use it for other purposes. VMI enables multi-frequency delivery schedules, allowing orders to arrive in smaller, more manageable quantities when needed.

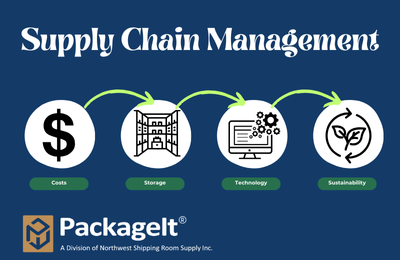

Operational and Cost Benefits Beyond Waste Reduction

Besides packaging waste reduction, vendor-managed inventory packaging solutions deliver a range of operational advantages:

- Lower Storage and Carrying Expense. VMI frees up your warehouse, resulting in lower storage and transportation costs. Invest that money elsewhere in the business!

- Less Administrative Workload. Remove manual stocktaking, reorder requests, and emergency supply runs from your team’s to-do lists and focus on higher-value tasks instead.

- Better Supply Chain Responsiveness. Are you going through demand spikes or seasonal surges? Your specialist is already aware of the patterns and is

ready

to adjust deliveries. Handle fluctuations with agility and adaptability.

- Strengthened Vendor-Customer Collaboration. Perhaps most importantly, you become

partners

with your supplier, trusting each other through transparent communication, shared data, and aligned objectives. Strategize together with accountability.

Real-World Applications: VMI in Action

PackageIt believes in VMI’s role in packaging waste reduction because we witnessed it ourselves

with Imaginetics, a globally respected aerospace manufacturing company operating from facilities in Auburn, Washington, and Gilbert, Arizona.

Imaginetics turned to our VMI program, and the impact was immediate. Roxann Lottes, the company’s human resources assistant, said it alleviated day-to-day stress for their internal teams. Whenever they ran out of packing slips or boxes, their specialist always had them delivered the same day or scheduled same-day will-calls.

Imaginetics also saved money because we kept the stock under control, avoided obsolescence, and offered bulk pricing. We took over the responsibility of running their extensive inventory, saving them time and effort as well.

Here are all the things we did for Imaginetics and other businesses that opted for

our VMI programs:

- Visited facilities on a regular schedule

- Learned product lines, day-to-day workflows, and goals

- Sourced essential supplies and negotiated competitive pricing

- Took charge of supply chain coordination and all aspects of inventory replenishment

- Monitored lead times and forecasted delivery timelines

- Tracked supply usage and identified trends for data-driven decisions

- Maintained complete visibility and transparency across inventory levels

- Met the end-users

- Shared packaging tips

PackageIt is an

all-in-one provider for all our clients. Our promise?

Personal

VMI services. Not everyone can guarantee that!

Experience Our Vendor-Managed Inventory Packaging Solutions

By combining precision forecasting, lean management, and strong partnerships, vendor-managed inventory (VMI) services enable brands to reduce packaging waste

and

enhance their operations. At PackageIt, sustainability and efficiency should go hand in hand, and our VMI programs demonstrate that this is indeed possible.

Discover how VMI for smarter packaging inventory management can move your business forward! Call (888) 743-0907 to speak with our experts or contactus online for a custom PackageIt VMI plan.

Sources:

Summary

Vendor-Managed Inventory (VMI) is a powerful solution to the costly and persistent problem of packaging waste, which often results from overstocking, obsolescence, and damage. VMI empowers the supplier to manage a buyer's inventory, ensuring just-in-time (JIT) delivery and optimal stock levels.

VMI reduces waste through five key mechanisms. It enforces

lean inventory management by aligning shipments with actual consumption to prevent surplus. It uses

improved forecasting based on real data to cut unnecessary orders. It avoids

obsolete or expired stock through tight "first in, first out" control and reduces product

damage with professional handling and storage. Finally, VMI’s multi-frequency, smaller deliveries

reduce the need for bulk storage.

Beyond sustainability, VMI offers significant operational benefits, including lower storage costs, reduced administrative workload, and better responsiveness to demand spikes, strengthening the partnership between vendor and customer. By making smart packaging choices, businesses can achieve both sustainability and efficiency.