In short, custom foams may be the one thing standing between utter product damage and safe storage and transport.

Learn more about these unsung heroes of packaging and shipping, and where you can go for the best

custom foam shipping supplies for your business.

Foam Is Great — But Custom Foams Are Better

Reading this, you might be wondering: “Isn’t all foam the same?”

We get asked this question a lot. Here’s our answer.

There’s no doubt that foam does the same thing, and that’s to provide a safe cushion for your delicate packages. However, when you think about it, not all packages are the same. Some take on different shapes, and others are sensitive to even the slightest application of pressure.

Once you factor these nuances in, you’ll know that ordinary foam won’t cut it. You’ll need custom foam packaging supplies for your products to get the protection they deserve.

Why Custom Foam Shipping Supplies Are Better

There are numerous advantages custom foams have over commercially available ones. Here’s what you can look forward to when you choose customized foam for your shipping needs.

Excellent Product Protection

One of the most salient benefits of choosing custom foams is product protection.

With commercially available foam, your products do get impact protection. However, there’s little to no accommodation for when your products take on a unique shape.

Choose commonly available foam for your products, and you’ll risk damage.

Luckily, custom foam can be tailored to the exact specs, dimensions, and pressure tolerance of the products you’re shipping. As a result, your products receive the right kind of protection from impact and unnecessary pressure.

Reduced Shipping Damage (and Returns)

Improved Sustainability and Reduced Waste

Of course, there’s always void fill, but did you know that void fill contributes

just as much environmental waste as non-biodegradable packaging materials?

If your brand has sustainability targets, you may be better off without void fill. Instead, you can opt for product protection options tailored to your product’s exact shape and dimensions — options like custom polystyrene and polyethylene foam.

These types of foam are customizable to fit any box and product contour. Choose these shipping supplies, and you can prescribe specific cuts for bespoke product fit.

There will be no need for void fill, and you get to meet your sustainability targets.

An Enhanced Unboxing Experience

As a packaging solutions provider, we’re big on ensuring you provide your customers with a premium unboxing experience. If you want to boost your brand identity while providing a quality customer experience, you can’t go wrong with adding custom foams to your packaging.

Besides protecting your products, customized foams are excellent additions to your packaging. With them, you can make a lasting impression and position yourself as a brand that actually cares about what your customers experience.

You won’t need to look far if you need proof of how custom foams boost the unboxing experience. Just think of brands like

Etsy and

Dior. Even Tiffany & Co. is big on custom foam inserts for jewelry protection and for providing a premium unboxing experience.

You Might Need Custom Foams in These Lines of Business

Granted, not every business needs custom foam for product protection. However, you might need it if you’re in the following industries.

Food and Beverage

Besides temperature-controlled packaging, custom foam should be another addition to your packaging arsenal if you’re shipping food products. The bespoke cushioning provided by custom foam can prevent your food and beverage products from being crushed during shipment.

Pharmaceutical

Drugs and medical supplies are some of the most delicate products that can be shipped. If you’re transporting any of these products, you’ll need all-around protection from pressure and impact, which you’ll get with custom foams.

Electronics

Besides drugs and food, electronics are sensitive to various conditions, like pressure and impact. For example, tablets can sustain damage to their screens without sufficient cushion. Also, there’s always a chance of scratches when your foam isn’t cut to fit your electronics perfectly.

When it comes to protecting your electronics from pressure and impact, there’s a way you can hit two birds with one stone — and that’s to customize your packaging foam for fit.

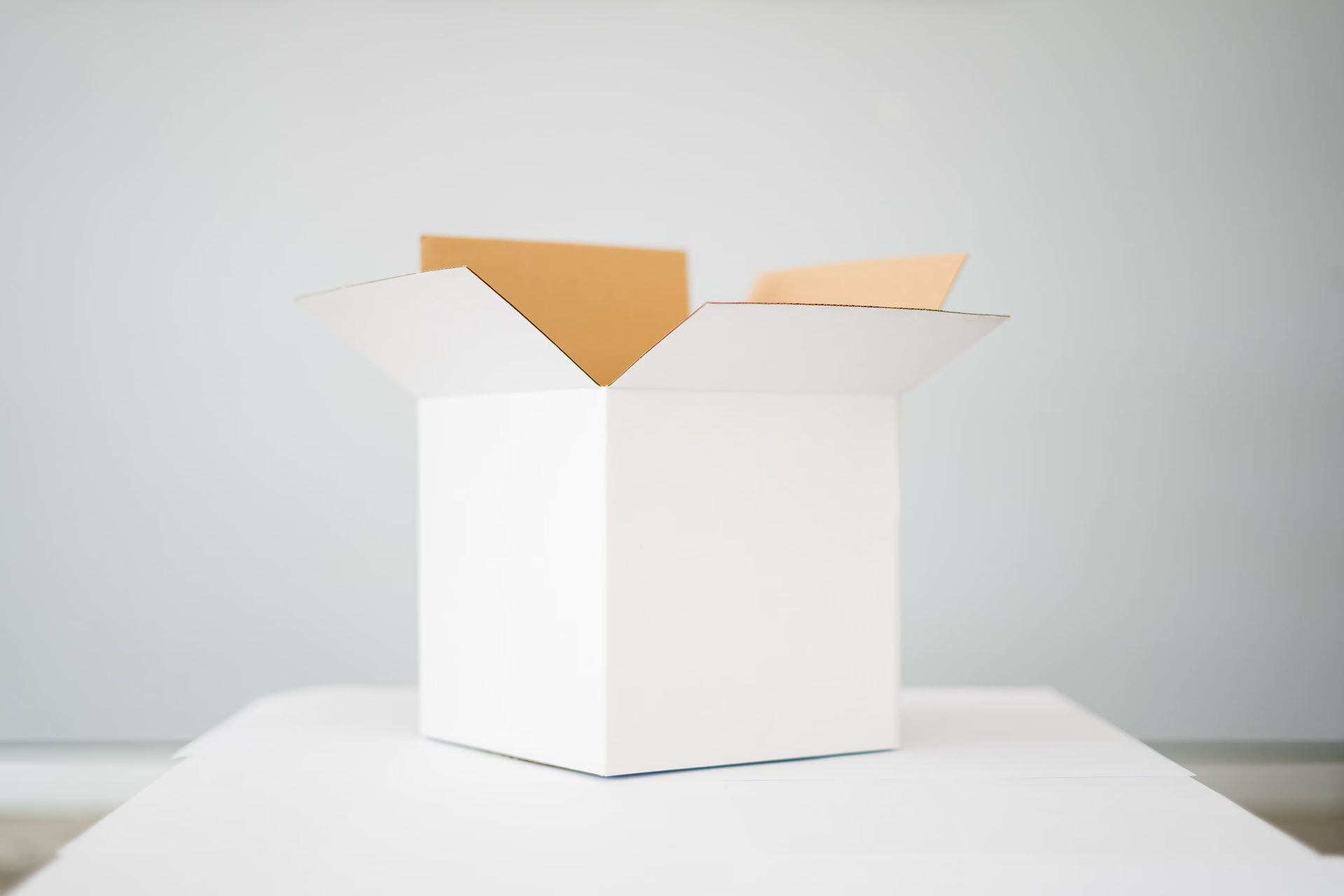

Custom Foams by PackageIt

It’s not always easy to find bespoke foam for your shipping needs. Luckily, at PackageIt, we offer custom foams designed to protect your products from pressure and impact.

From our polyethylene foam to polystyrene custom foam, there’s always an option available. Choose from our selection of

custom foam shipping supplies and give your products the protection they deserve.

Expanded Polystyrene (EPS)

Are you prioritizing lightweight yet superior protection? Look no further than expanded polystyrene (EPS) foam if you are. EPS is one of the most cost-effective materials for providing significant cushioning with minimal weight addition to your shipments.

What makes EPS particularly valuable is its excellent insulating properties. In fact, you’ll often find it in temperature-sensitive packaging applications.

Whether you’re shipping perishable foods or temperature-sensitive pharmaceuticals, EPS helps maintain the required temperature range during transit.

EPS also boasts versatility. It can be precision-cut into custom pads or hot wire cavity cut to create perfect-fitting enclosures for oddly shaped products.

Its customizability makes it a tailored solution that eliminates movement and provides uniform protection throughout shipping.

Polyethylene Foam

If water resistance is a concern for your products, a few custom foam options can match polyethylene foam.

Unlike some other foams, polyethylene features a closed-cell structure that prevents water absorption. This is a critical feature when shipping products that could be exposed to moisture during transit.

Our polyethylene foam comes in various forms, including plank form for larger applications and roll stock for more flexible packaging needs. Because we offer customized options, you can choose from multiple thicknesses and densities depending on the level of protection your products require.

Did we mention how versatile it is? Like EPS, the versatility of polyethylene foam extends to its fabrication options. It can be die-cut for precise shapes, heat-sealed for custom enclosures, or saw-cut for straight edges.

Polyurethane Foam

For the ultimate in cushioning comfort, polyurethane foam stands out from the crowd. Its open-cell structure provides a soft, sponge-like quality that’s perfect for delicate items requiring gentle but effective protection.

Polyurethane is easily transformable into the familiar “egg carton” pattern (convoluted foam) that many associate with premium packaging. This design looks professional and provides targeted pressure relief and shock absorption.

What’s particularly appealing about polyurethane is its ability to conform to product shapes over time. Its moldability creates an increasingly customized fit with each use, ideal for returnable packaging systems or cases designed for multiple uses.

Anti-Static Foam for Electronics

If you’re in the electronics industry, you know that static electricity is your product’s worst enemy. Even a slight static discharge can render sensitive components useless. This is where anti-static foam becomes indispensable.

Available in both polyethylene and polyurethane variants, anti-static foam can dissipate static buildup that could damage electronic components. It’s typically dyed pink for easy identification in warehouses and shipping areas.

Cross-Linked Foam

When only the highest level of protection will do, cross-linked foam represents the premium tier of foam packaging solutions. This extremely fine closed-cell polyethylene foam offers a smooth, uniform texture that looks and feels professional.

The unique manufacturing process of cross-linked foam creates a material with superior durability and resilience compared to standard polyethylene. Because of its exceptional resistance to water absorption, it’s ideal for marine applications or products that might face extreme shipping conditions.

Perhaps most impressive is cross-linked foam’s ability to meet “Class A” surface protection standards. Look no further if you need luxury protection for luxury goods, high-end electronics, or any product where the presentation is just as important as protection.

Choose a Packaging Partner That Isn’t Soft on Protection

When it comes to product protection, what’s on the outside is just as important as what’s on the inside. For quality custom foams that give your products all-around protection, we’re a call away.

Contact us today for a free quote on our custom foam shipping materials.