Packing Supplies

Packing supplies form the foundation of any successful shipping operation. They protect the products during transit and ensure safe handling and efficient storage. Here are some essential packing and packaging supplies that you should always have in stock:

- Cardboard boxes

- Shipping envelopes and pouches

- Bubble wrap

- Packing peanuts

- Tape

- Labels

- Markers

Choosing suitable materials ensures the safety and security of your shipped items and positively reflects on your

brand image. It’s crucial to regularly check the quality of your packing supplies and replace them when necessary. Damaged or worn-out supplies can compromise the safety of your products and lead to damages during transit.

To optimize your packing processes, consider implementing efficient packing techniques that minimize waste and maximize efficiency. These could include:

- Using the correct box sizes

- Consider custom boxes or packaging

- Investing in automated packaging equipment

- Training your staff on proper packing procedures

- Implementing a quality control process for all packed items

You can streamline your packing operations and deliver a superior customer experience with the right supplies and techniques.

Shipping Materials

Once your items are securely packed, it’s time to focus on

shipping supplies that ensure a safe and timely delivery. These supplies protect your packages during shipping and play a crucial role in maintaining your brand reputation. Here are some essential shipping materials to keep in stock:

- Shipping labels

- Envelopes

- Mailers

- Shipping scales

- Shipping tape

- Foam inserts.

- Corner protectors.

- Strapping and ties

- Stretchwrap

Warehouse Equipment

No warehouse is complete without reliable equipment to streamline storage, organization, and transportation processes. Investing in the right

warehouse equipment not only promotes efficiency and productivity but also ensures the safety of your staff. Depending on the size of your operations, here are some essential warehouse supplies to keep on hand:

- Pallets

- Shelving and racking systems

- Forklifts

- Material handling carts

- Conveyor systems

- Hand trucks and dollies

Proper warehouse equipment is crucial for streamlining logistics operations’ storage, organization, and transportation processes. Investing in the right equipment boosts productivity and minimizes the risk of workplace injuries, creating a safer environment for warehouse staff.

Consider the following factors when choosing your warehouse equipment:

- Warehouse size

- Warehouse layout and design

- Type of products stored

- Weight and size of products

- Storage and transportation needs

Safety Gear

It is important to prioritize the safety of your warehouse workers. Providing adequate safety gear — including gloves, safety glasses, and high-visibility vests — is essential for reducing the risk of accidents and injuries in the warehouse environment.

In addition to providing safety gear, it’s crucial to implement comprehensive safety protocols and ensure compliance with industry regulations. Here are some standard safety practices to consider:

- Regular equipment maintenance and inspections

- Adequate training for all warehouse staff

- Clear signage and labeling for hazardous areas or materials

- Proper storage of dangerous substances

By implementing proper safety measures, you prioritize your employees’ well-being and minimize accidents and downtime in your operations.

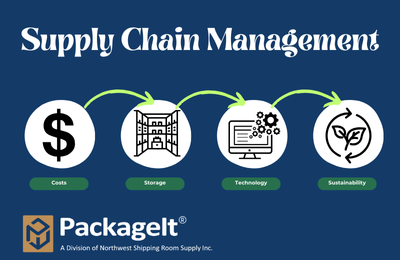

Final Thoughts

Maintaining an efficient and well-equipped warehouse is essential for the success of any shipping and packaging business. Regularly evaluating and updating your supplies, equipment, and safety measures can ensure smooth operations, enhance productivity, and deliver a superior customer experience.

At PackageIt, we’re committed to helping you optimize your warehouse facilities with our comprehensive selection of supplies and equipment. The success of your shipping and packaging operations is our top priority, and our specialists are here to support your business every step of the way.

Contact us at

888-743-0907 or visit

packageit.com for personalized solutions.