Advanced Packaging Supplies and Equipment for Efficiency

What makes packaging supplies and systems “advanced?” What are the features and applications that elevate products and systems from more traditional methods? There are several hallmarks, but the most important ones are the use of automation, real-time tracking, and even smart technology.

These features help streamline the packaging stage of warehousing operations, reducing the need for manual labor and improving your company’s overall efficiency.

Some popular examples of advanced packing supplies and equipment are the following.

- Automated sealing machines

- Robotic arms for sorting

- Conveyor systems

- Laser barcode scanners

- Vendor-managed inventory programs and software

The Benefits of Automated Packaging Systems

When you incorporate automated packaging systems into your warehousing operations, you can leverage the following key benefits:

Increased Speed and Efficiency

Automated systems can operate at high speeds with minimal oversight from human technicians. You won’t need additional manpower — which can be prone to errors — for tasks like sealing, labeling, and sorting. You can ensure a

higher output and reduce error rates.

Consistent Outputs

Automation ensures uniformity in packaging, reducing errors, and inconsistencies. For example, the

MINI PAK’R available through PackageIt creates consistent air cushioning for packaging boxes and padded envelopes. The RFID technology ensures this uniformity by automatically adjusting air volume and seal temperature.

Decreased Labor Costs

Given how you can automate many aspects of your warehouse operations, you can significantly reduce the need for manual labor. You can lower operational costs while also avoiding the possibility of labor shortages during peak season.

Added Scalability

Whether it’s peak or lean season, an automated packaging system lets you easily adjust warehousing operations. You won’t have to make major adjustments to your infrastructure or workforce.

Essential Packaging Supplies for a Well-Equipped Warehouse

Before you begin integrating more advanced packaging systems into your operations, you should have the following essential supplies to ensure a continuous packaging and shipping process.

- Cardboard or Corrugated Boxes:

Come in different dimensions to accommodate different types of products

- Envelopes and Pouches: Ideal for small packages and documents

- Tape: For all-around sealing and packaging needs

- Packing Peanuts/Foam Products/Bubble Wrap: Lightweight yet sturdy ways to protect products from blunt force and rough handling

- Labels: Necessary for clear identification and tracking

For a complete list of basic packaging supplies, see our

checklist.

Once you have the essentials, you can begin incorporating advanced systems and machines as demand for your products increases. Some examples in our inventory are the following.

- MINI PAK’R:

An air cushion system that provides on-demand protection for small packages, this product is ideal for small businesses and e-commerce companies.

- Pregis Easypack Quantum XF:

This

paper packaging system crumples large amounts of paper to use as void fill and wrapping. It’s ideal for packing sharp objects as well as loose or unboxed items.

- Pregis Easypack Packmaster:

The

Packmaster from Pregis is another paper packaging system that can covertly paper up to 80 times its original volume, working in automatic and semi-automatic modes for customizable control.

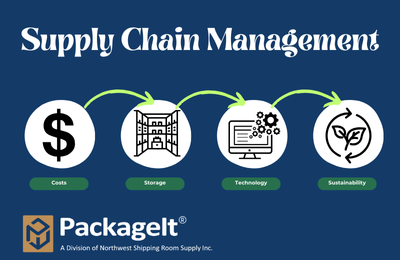

How Vendor-Managed Inventory Programs Can Streamline Operations

Vendor-managed inventory programs (VMIs) work as a service that further pushes the benefits of advanced packaging solutions. With a

VMI, packaging suppliers like PackageIt can manage your inventory and free up resources on your end. Here are the benefits you can expect when you leverage VMIs for warehouse operations.

- Reduce Stockouts and Overstocks: With our active monitoring, we can ensure that the stock of packaging supplies remains within ideal numbers.

- Lower Inventory Costs:

By allowing us to manage inventory, you can reduce carrying costs. These include storage, insurance, and obsolescence expenses.

- Improved Forecasting and Demand Planning: We can provide insights on sales data and trends. Using this information, you can more accurately plan for future packing supply demands.

- Focus on More Productive Aspects of Your Business: VIMs take away the burden of having to manage packing supplies. That way, you can shift your attention to more critical aspects of our business-like sales and marketing.

Wrapping Up: Advanced Packaging Solutions for More Efficient Operations

Seamless warehousing operations ensure that you’re able to efficiently pack and ship your products to customers. You can achieve this goal through modern packaging equipment and products. With automated and advanced machinery like what PackageIt can provide, you can be one step closer to maximum efficiency, consistent outputs, and more fine-tuned processes. For more details about solutions available for your business, please

get in touch with us today.