How A VMI System Works

VMI programs differ from traditional inventory management systems through three key aspects:

- Vendor and producer share information.

- Vendors have control over inventory management.

- Vendors are responsible for restocking and ordering.

VMI thrives on robust communication between buyers and sellers. Both parties collaborate to define success metrics and finalize the partnership’s terms and conditions. Then, the vendor starts supplying products to the producer/seller.

Throughout the operation, the producer/seller share information regularly, allowing the vendor to track stock levels and buying patterns accurately. With this information, the vendor efficiently replenishes inventory as needed. Moreover, the insights into production schedules, potential shipping challenges, and lead times allow effective shipment scheduling.

Does Your Company Need A VMI Program?

Deciding whether you need a VMI is a strategic choice that can significantly influence your business’s efficiency and profitability. Understand the motivations to see how such a system aligns with your business objectives and operational requirements.

Improved Inventory Management

One key

reason for adopting a VMI program is the enhanced capability to manage inventory. By allowing the vendor to take charge of inventory levels, companies can reduce the incidence of overstocking or stockouts, improving overall inventory turnover.

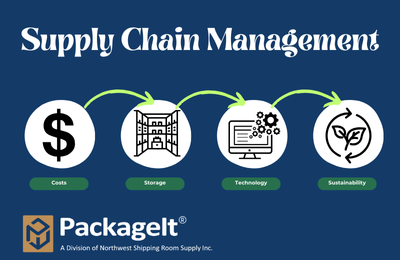

Cost Reduction

Packaging supplies vendors optimize delivery schedules and routes. As such, VMI programs can lead to substantial cost savings in several areas, including reduced inventory holding costs, minimized ordering costs, and potentially lower transportation costs.

Enhanced Partnership and Collaboration

Implementing a VMI program fosters a strengthened partnership between producer/suppliers and vendors. This close collaboration can lead to better communication, improved forecasting accuracy, and a more synchronized supply chain.

Smoother Business Operations

VMI can enhance the supply chain’s efficiency by streamlining business processes and reducing inventory discrepancies and errors. Automating inventory management allows businesses to focus on other critical areas and reduce manual labor costs.

Increased Sales and Customer Satisfaction

Effective VMI programs often increase product availability, leading to increased sales. Further, by ensuring that the right products are available at the right time, customer satisfaction can significantly improve.

PackageIt’s VMI Program

Partnering with a reliable VMI provider makes all the difference in implementing a successful VMI program. PackageIt is a premier provider for all your packaging, shipping, and warehousing requirements, specializing in

unparalleled VMI services.

Free for Qualifying Companies

PackageIt stands out by offering our comprehensive VMI services free of charge for qualified companies. This initiative underscores our commitment to fostering strong, mutually beneficial partnerships and enhancing supply chain efficiency for our clients.

Dedicated VMI Specialists

At PackageIt, we understand the importance of personalized service and specialized support. Our VMI program assigns dedicated VMI specialists to every client. These specialists work closely with our clients to analyze their needs, challenges, and business objectives and provide customized solutions that optimize the supply chain.

Weekly, Bi-Weekly, or Monthly Visits

Our VMI specialists conduct weekly, bi-weekly, or monthly visits to assess stock levels, identify demand patterns, and adjust inventory replenishment plans accordingly. These regular visits facilitate a proactive inventory management strategy and strengthen the partnerships.

Continuous Improvement

PackageIt regularly evaluates processes, analyzes data, and collaborates with clients to identify areas for improvement. By implementing enhancements and streamlining processes, we ensure optimal efficiency and value for our clients.

PackageIt: Packaging Supplies With VMI

Despite the constantly changing

trends in warehouse and packaging supplies, PackageIt’s vendor-managed inventory services ensure your business remains well-supported. With us, you can experience the difference in a logistics relationship that moves beyond mere transactions to become a pivotal part of your business growth.

Discover how a strategic VMI partnership can turn your inventory challenges into your biggest advantages. Reach out to PackageIt’s specialists today!