Inventory management is challenging for warehouse managers and small business owners. Managers must balance opposing demands to have adequate inventory on hand to cover all contingencies while also avoiding expensive, ineffective overstocking. In addition, It can be extremely challenging due to demand estimates and changing costs, particularly in Seattle and the surrounding areas.

What if you used a vendor-managed inventory solution that takes good care of all aspects of inventory management?

What Is Vendor-Managed Inventory?

Vendor-managed inventory, also known as VMI, is an effective method of inventory management where a manufacturer or other product provider is responsible for making the best use of the inventory that a distributor has on hand. VMI is a framework where suppliers control pre-determined inventory levels. In other words, the supplier makes choices on the end-user’s behalf and continually replenishes the inventory based on needs and goals.

The Need for Vendor-Managed Inventory for Warehouse Supplies

Pros of VMI

With how VMI operates, it provides a variety of benefits to small business owners, warehouse managers, procurement officers, and shipping and fulfillment center managers. The pros of VMI include:

- Lower carrying costs

- Reduced need for safety stock

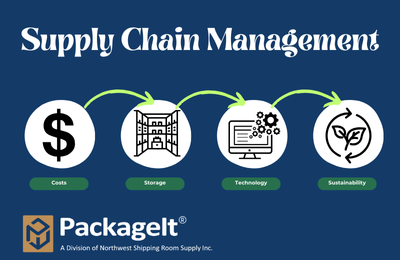

- Effective supply chain management

- Improved communication with all warehouse departments

- Improved data insights

- Accelerated execution

- Smoother business operations

- Reduced productivity and cost

Cons of VMI

Although VMI has many advantages, there are a few drawbacks to take into account. Cons of VMI include:

- Less control on inventory management: You may have less control over inventory management because you will be depending on a third party to handle your inventory.

- Satisfaction is not guaranteed: Although VMI is beneficial, you might not be satisfied with how your inventory is being handled.

- Sharing data: It is important to share insights and data with the VMI provider to have great results; however, it may be uncomfortable for some.

PackageIt VMI Services

Finding a trustworthy and reputable VMI service provider is crucial given how important proper inventory management is for a business.

PackageIt is a top-ranked solution provider of packaging, shipping, and warehousing needs and we specialize in offering top-of-the-line VMI services.

Warehouse supplies packaging trends in Seattle and the entire United States continue to fluxuate, but utilizing PackageIt VMI services can guarantee your company is not left high and dry. Our VMI service is designed and can be tailored to meet your needs and help you achieve your goals. You will have control over how you want your warehouse supplies inventory to be handled and our experience and knowledge will improve the process to ensure great results. As a top-ranked VMI service provider, we make sure to take care of all of your information and data insights and use it only to your advantage.

Get in Touch With Us About Your Warehouse Supply Needs Today!

Make sure your warehouse personnel have everything they need to perform at their highest level. PackageIt’s service is unrivaled in the business thanks to our wide range of products, low costs, and knowledgeable team. PackageIt provides complete and premium VMI services, including products and services for full packing, shipping, and warehouse supplies.

Contact us today and learn more about how our expertise and knowledge in the warehousing industry can help you achieve high-level business success.