If you regularly ship products for your business, you may be familiar with foam inserts. Foam is a popular packaging material due to its ability to protect and cushion items during shipping. However, choosing the right type of foam can be tricky. Here are some tips on how to determine which foam meets your needs.

What Are the Different Foam Types?

Let’s go over some of the most commonly used packaging foams, their benefits, and their uses.

Polyurethane Foam

Polystyrene Foam

Polystyrene foam, or styrofoam, is a lightweight, rigid, closed-cell foam derived from polystyrene. It is often used in packaging, insulation, disposable food containers, and as a core material in construction for insulation purposes.

The primary advantage of polystyrene foam is its weight — it’s incredibly lightweight, making it ideal for packaging and construction materials. Additionally, polystyrene foam has excellent thermal insulation properties, perfect for keeping items at a stable temperature during shipping or storage.

Polyethylene Foam

Polyethylene package foam is a closed-cell foam made from polyethylene, a widely used plastic. It is flexible, lightweight, and resistant to moisture and chemicals.

Polyethylene foam is used in packaging for cushioning fragile items, protective padding in sports equipment, marine buoyancy aids, and insulation in HVAC systems. We also offer an

anti-static option for packaging sensitive electronics.

This packaging material is flexible and can conform to the shape of the product being packaged, providing a snug fit and excellent cushioning. Polyethylene is also resistant to water absorption, which helps protect products from moisture damage.

Expanded Polyethylene Foam (EPE)

Cross-Linked Polyethylene Foam

Cross-linked polyethylene foam is a type of polyethylene foam that has

undergone cross-linking, which enhances its physical properties. This foam is used in applications where durability and performance are critical, including automotive components, sports equipment, medical devices, and so on.

Cross-linked polyethylene package foam typically has a higher density than other foam materials, offering enhanced protection against impacts for longer periods. This material is also resistant to many chemicals, making it suitable for packaging items sensitive to chemical exposure.

Our Custom Package Foam Options

Custom package foams are an excellent option to suit your unique

packaging needs. Whether you’re shipping small pharmaceutical supplies or sensitive electronic equipment, PackageIt can customize the perfect packaging foam for you. You can choose from our extensive selection of package foam material or our experts can recommend one if you are unsure about what you need.

How To Choose the Best Material for Your Products

Choosing the most suitable foam material for your shipment is crucial in ensuring the safe delivery of your products. Here are some factors to consider when determining your foam needs:

- Type of product: Fragile items may require a more shock-absorbent material, while heavier items may need a denser and sturdier foam.

- Level of protection needed: Consider the potential risks during shipping or handling, such as impacts, vibrations, and moisture. Choose a foam material that can withstand these hazards.

- Cost: Different foam types vary in price, so consider your budget when selecting the best option for your packaging needs.

- Environmental impact: If sustainability is a priority, opt for reusable or recyclable materials, such as polyurethane or expanded polyethylene foams.

Depending on the fragility and shape of your items, you may also need to use additional package protection products, such as bubble wraps, airbags, or corrugated inserts.

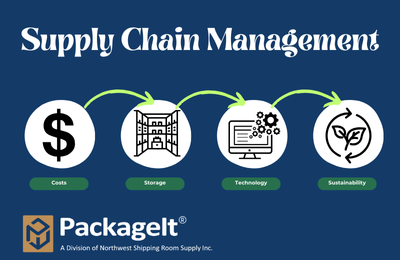

Get All Your Packaging Needs from PackageIt

Today, shippers have more expansive options regarding their shipping needs. From different foam types to packaging designs and materials, there is a solution for every product and budget.

At PackageIt, we offer a wide range of packaging products and solutions to meet your needs. Contact us today and learn more about our products and customized options.