Warehouse and supply chain managers play a critical role in the success of any organization, particularly during peak season. Peak season refers to a specific period when demand for products or services is significantly higher than usual. It is a time of increased sales, intense customer activity, and heightened logistical challenges.

We briefly explore this concept, its implications for warehouse managers and shipping managers, and outline some effective planning strategies.

What Is Peak Season?

When Is Peak Season?

The timing of peak season varies across businesses. For example, as mentioned, the retail industry often experiences peak season during the holiday period, from late November until December. This is when consumers actively shop for gifts and take advantage of seasonal discounts. The e-commerce sector also witnesses a surge in demand during key shopping events like Black Friday and Cyber Monday.

Other industries, such as the transportation and logistics sector, may experience peak season during different times of the year. For instance, the logistics industry often faces peak season during the summer months when companies increase their shipping activities due to factors like vacations, construction projects, and seasonal inventory replenishment.

How Has Peak Season Changed?

How To Plan for Peak Season

Effective planning is crucial for warehouse and supply chain managers to successfully navigate peak season. Here are some strategies they can implement:

Vendor Management Inventory

Implementing vendor managed inventory (VMI) can help streamline inventory management during peak season. VMI allows suppliers to monitor and replenish stock levels at the warehouse, ensuring optimal inventory levels are maintained. This approach reduces the risk of stockouts and improves overall supply chain efficiency.

Forecasting and Demand Planning

Utilization of advanced forecasting techniques and historical sales data to accurately predict customer demand during peak season. This information can guide inventory levels, resource allocation, and transportation planning. Machine learning algorithms and predictive analytics can be valuable tools in this process.

Collaboration and Communication

Establishing strong relationships with suppliers, carriers, and other stakeholders in the supply chain. Effective communication ensures everyone is aligned and can react quickly to unexpected challenges. Collaboration can also help identify potential bottlenecks and implement contingency plans.

Increase Workforce Capacity

During peak season, enterprises may require additional staff to manage increased order volumes. Hiring temporary or seasonal workers, cross-training existing employees, and utilizing automation technologies can help handle the workload efficiently.

Optimize Warehouse Layout and Processes

Analyze warehouse operations to identify areas for improvement. Reorganize the layout to minimize travel time, implement efficient picking and packing processes, and leverage technology such as warehouse management systems (WMS) and automation to enhance productivity.

Handle Peak Seasons Like a Pro

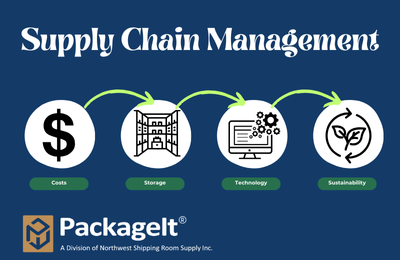

Peak season poses both challenges and opportunities for warehouse managers and shipping managers. By understanding the concept, identifying its timing, adapting to changing dynamics, and implementing effective planning strategies, managers can ensure the smooth flow of operations.

Do you need help with your shipping supply inventory, forecasting, and optimization efforts? At PackageIt, we offer custom solutions for warehousing, shipping, and packaging requirements including a top

VMI program. Call us at (888) 743-0907 to discover how we can help you handle peak season like a pro.Z