Not even the best economists can predict when a

significant economic recession will happen. And while recession is a normal part of the economic cycle, when the economy's decline is substantial, it can severely impact many people's lives. This downturn of events can change buyer activity resulting in a decrease in sales.

So, during this time it is essential for business owners and marketers to change their strategies to stay afloat or even grow. This includes evaluating packaging needs as buyers change. We wanted to take a look at how you can innovate your packaging supplies as buyer behavior changes in the current economy and possible recession.

What You Can Do

There's no one correct way to "recession-proof" your business. You need to tailor your approach to match your products, services, and buyers.

Still, you can do some things to help ensure you are packaging smarter.

Consolidation of SKUs

Procure What You Need in Advance

You should always have a good idea of how much packaging your products will need. However, during an economic recession, it's doubly important to know your packaging supplies well in advance.

This knowledge will help you avoid any potential issues with supply chain disruptions or price hikes. Make sure to procure what you need before the recession hits, so you're not caught off-guard.

Rightsizing Your Materials

Rightsizing your materials means using the minimum amount of packaging necessary to protect your product. This will help you save on costs while ensuring your product arrives safely to your customers.

Stay away from

"one-size-fits-all" packaging as this can do more harm than good. Use custom-sized packaging instead, so you're not wasting any materials while ensuring that your product will arrive safely to your customers.

Reconsider the Way You Do Bags

Rightsizing Loads

When you're shipping supplies, you want to ensure you're using the most efficient method possible. This includes reconsolidating your loads to reduce overall transportation costs.

For example, if you're shipping perishable goods, you might want to put your shipping goods into a suitable packaging to maximize space and minimize travel costs.

Downsizing Thickness of Stretch Wraps

Whenever you're shipping out cargo, you'll need to use some form of stretch film or wrapping to keep everything together. However, using too much stretch film can waste materials and money.

Instead, focus on downsizing the thickness of your film. This will help you save on costs without sacrificing the safety of your products.

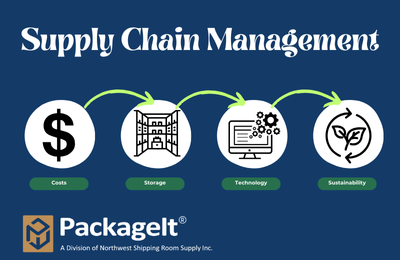

Expert Consultation

Ultimately, you'll want to consult with an expert to help you make the best decisions for your business operations. At

PackageIt, we are packaging industry experts. We can help you understand the current market landscape and develop a packaging strategy to help improve your efficiency, decrease costs and stay on top of buyer behavior and the shifting economy.

Remember, different businesses will have different needs and goals, so it's important to customize your approach to meet your production goals while minimizing the impact of the recession.