Are you an online business owner struggling with damaged products during shipping? If you are, you might be choosing the wrong kind of boxes. When it comes to choosing a box that protects your products during shipping, opt for corrugated boxes.

Corrugated boxes are one of the most resilient kinds of boxes for packaging and shipping. Not only are they durable, but they are also

customizable — capable of being shaped based on your business’s needs.

Find out more about what corrugated shipping boxes are, how they compare, and why you should use them.

Let’s Start With the Numbers

What Is Corrugated Cardboard?

Corrugated cardboard is a material consisting of multiple sheets of cardboard. These sheets of cardboard are layered on top of each other with the outermost sheets sandwiching an inner layer. This inner “fluted” layer is lined with ridges where box manufacturers apply glue. The glue binds the outer layers that envelope the fluted layer, creating one sheet that consists of three layers of dense cardboard.

The multiple layers give corrugated cardboard its density and durability. As a result, anything packaged using corrugated cardboard contains multiple layers of protection from the stresses of shipping and handling.

Corrugated boxes consist of panels of corrugated cardboard.

What Are the Advantages and Benefits of Corrugated Cardboard for Shipping?

This vs. That Terminology

Corrugated vs. Cardboard

Cardboard and corrugated cardboard might look similar on the surface, but there’s a lot more than what you see on the surface — especially when you take a cross-sectional look at these materials.

Cardboard

Cardboard consists of either paper stock or paper pulp. The consistency of cardboard is rigid enough to be used for boxes that house soft items. If you’re a company selling school supplies or anything that doesn’t need much protection, cardboard suffices. In fact, many retailers use cardboard as their packaging material of choice.

Corrugated

Corrugated boxes take the protective qualities of cardboard and multiply it by a factor of three — literally. Corrugated cardboard consists of multiple sheets of cardboard layered on top of each other. What facilitates the compactness of the layering is the adhesion to the fluted layer, which is the ridged layer between the outer sheets of cardboard.

Mailers vs. Boxes

Once you have decided to choose corrugated material for your shipping and packaging, you’ll have to choose between mailers or boxes. Both will shield your products from the elements and the stresses of shipping and handling. However, each one is better for certain situations.

Mailers

Mailers (or mailer envelopes) encase contents in space-friendly ways. Because they’re envelopes, they’re easy to store and move around. However, what mailers have in easy portability they lack in 360-degree protection.

For this reason, mailers are a better option for companies that mail out smaller and more resilient items like clothing, stuffed toys, and cables. For more delicate products like electronics and ceramics, mailers aren’t a good option.

Boxes

Boxes encapsulate fragile goods in six panels of corrugated cardboard. Because of the material boxes consist of, boxes offer better protection and, in most cases, privacy.

Boxes are an excellent option for transporting virtually anything by mail. Unfortunately, because of the space they take, logistics companies will often transport boxed packages for a fee.

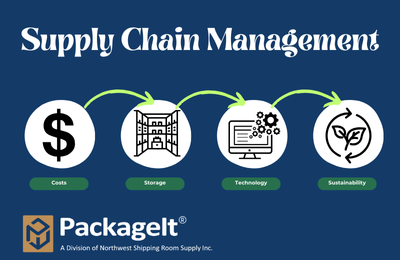

Think Out of the Box and Make Your Products Go Places

Successful shipping requires the right materials for packaging. Whether you’re choosing corrugated or other materials, go with a company that takes the guesswork out of warehousing, shipping, and packaging.

If you’re looking for such a company, look no further than PackageIt.

Speak to our account representatives today, and let us help you take your products securely from point A to B.