COMPOSITE & CORD STRAPPING

Used as an alternative to steel strapping:

Light, flexible, and contains no sharp edges. Easy to handle and dispose of. Fastening is accomplished utilizing a simple, economical tool and a high joint efficiency buckle. It stays tight on loads and can absorb impacts and load shifting that would normally break steel banding or damage valuable product.

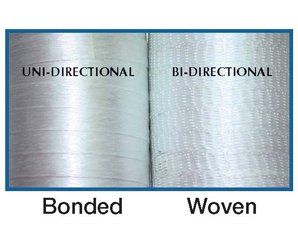

Composite Cord:

- Light, flexible and contains no sharp edges.

Woven Cord:

- Works like a flat rope with superior knot strength.

How to determine the correct strapping:

Steel:

- Pallet weight in excess of 2500 lbs.

- Sharp Edges.

- Non-compressible loads.

Polyester:

- Pallet weights up to 2500 lbs.

- Non-compressible or moderate settling loads.

- When polypropylene has failed, i.e. loads shifting or breaking.

Polypropylene:

- Pallet weighs up to 2500 lbs.

- Moderate settling loads.

- Most palletizing of corrugated boxes.

FAQ's

Q: Is composite cord strapping as strong as steel?

A: Absolutely. In fact, in break strength comparisons, composite cord strapping exhibits much higher impact resistance than steel. It requires a much higher tensile steel strap to absorb the same impact as composite cord strapping.

Q: How does composite cord strapping compare to traditional polyester strapping?

A: Extruded polyester strapping is not as soft and flexible, nor does it possess as much elongation and memory to absorb impacts. Extruded polyester strapping requires significantly more expensive sealing tools and their associated repair costs.

Q: How does composite cord strapping compare to woven cord strapping?

A: Although both products possess similar physical properties, woven cord strapping tends to shear at the fastener, resulting in consistently lower and often unpredictable joint efficiencies. Woven cord strapping has a propensity to slip at the fastener, unless a special phosphated buckle is used.

Q: How does composite cord strapping compare to polypropylene strapping?

A: Although polypropylene strapping has very high elongation, it has no memory so it does have good impact resistance. Polypropylene stretches out over short periods of time and is not suitable for heavy loads.

Q: How is composite cord strapping fastened?

A: The highest joint efficiency is achieved using a wire buckle and an economical manual-grade strapping tensioning tool. Seals can be used as well, but they are more labor intensive and do not achieve such high joint strength. Composite cord strapping cannot be heat sealed.

Q: Is composite cord strapping notch sensitive?

A: Nicks and cuts will not spread across composite cord strapping.

Q: How does composite cord strapping perform in extreme temperatures?

A: The physical strength of composite cord strapping remains virtually unchanged between -40 and 200 degrees fahrenheit.

Q: How does composite cord strapping perform when exposed to UV light?

A: The strength membranes of composite cord strapping exhibit excellent resistance to UV light. For added durability, the outer coating is treated with a UV inhibitor.

Composite Cord Strapping 8x8" Core

*Composite polyester strap is a plastic coated cord strap.

ITEM #

5002502

5004236

4003629

5005218

*2RL/CS Minimum

Joint Efficiency with Buckles

*Composite 80/30%

5004238

2221603

5004239

Tools

MUL325

W130

SIZE

5/8"

3/4"

3/4"

1"

5/8"

3/4"

1"

MUL 325 Tensioner

FEET/RL

2789

1965

1641

1640

Galv. Or Phosphate Coated

Galv. Or Phosphate Coated

Galvanized

W-130 Dispenser for Composite

STRENGHT

1650

1675

2205

2768

1m

1m

1m